Woodworking Bowl Blanks for Lathe Turning

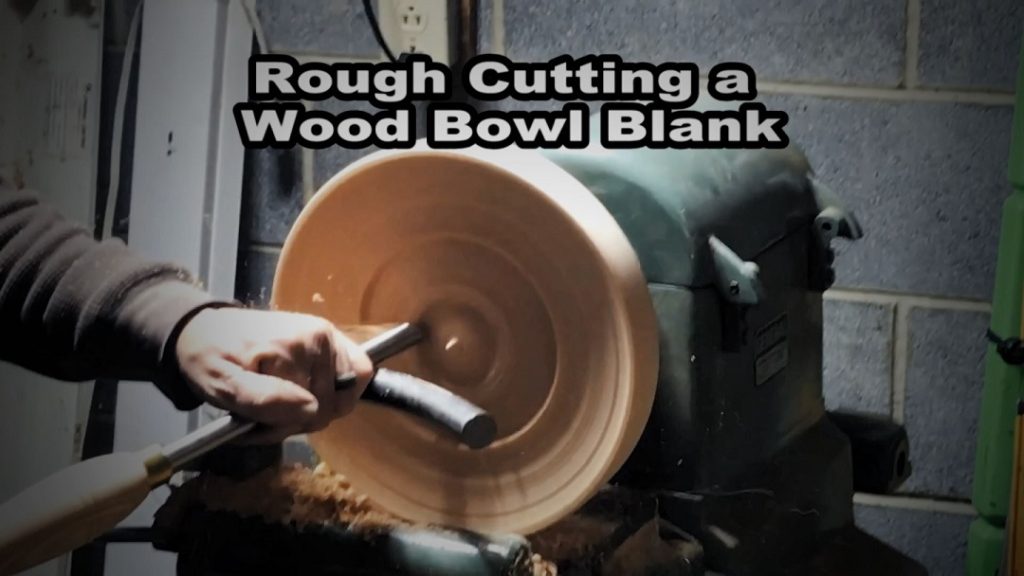

In this video Chuck is turning a bowl blank on the lathe. A bowl blank is a cube of wood cut so that the grain runs perpendicular to the rotation axis. You do not want wood pith (the wood at the very center of the log) in your bowl. Pith is the oldest part of the tree and has a greater tendency to crack. Typically, if your finished bowl contains pith, it will eventually fail.

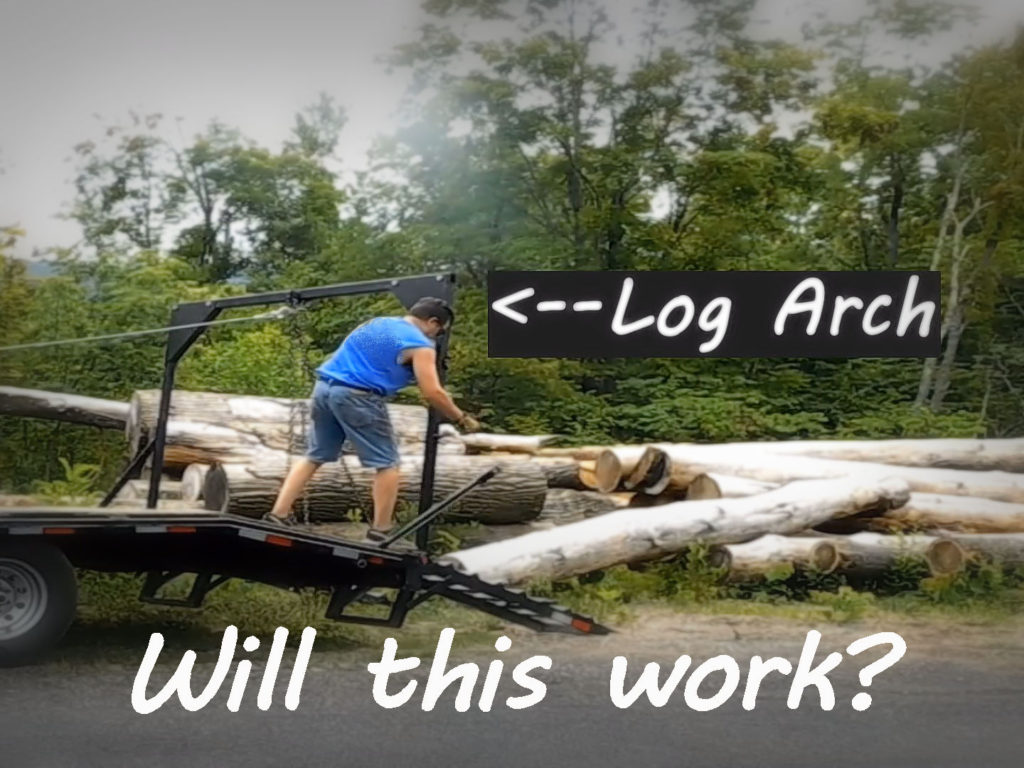

In order to make a bowl blank from a log, we first cut the log lengthwise with the grain and through the middle section to remove the pith. These half logs are squared up and cut into manageable blocks for bowl blanks.

Bowl blanks are roughed out on the lathe. This removes enough of the material to allow the bowl wood to dry, but also allows enough material so the bowl can be finish shaped at a later time. Chuck likes to let the rough-cut bowls dry slowly, so he packs them back into the shavings that he cut from them. If a rough-cut bowl dries too quickly, it will likely crack.

After these rough-cut bowls dry, Chuck will come back and do a finish turning followed by a wood finish of his choice to complete the project. If you are interested in bowl blanks from Pennsylvania hardwoods, please contact us at Pioneer Mountain Homestead.

#pioneermountainhomestead #brenchuckswood #raystownpa #raystownfarms #pmhomestead #lumberyard #lumber #treework #lumbermill #lumberman #roughcutlumber #roughcut #woodwood #woodisgood #wood #woodturner #woodlovers #woodcut #woodworking #woodcrafts #dowoodworking #woodgrain #woodworker #woodworkerlife #woodworkers #woodturning #woodworkcraft #woodworkingskills

Music:

“American Idle” by RKVC

https://www.youtube.com/channel/UCowgKeMGXKY038qwuf3yYlw/